INDUSTRY: MACHINERY & PLANT ENGINEERING

MORE EFFICIENCY AND BETTER SERVICE IN MACHINE AND PLANT TECHNICAL FIELD SERVICE THROUGH OPTIMISED SCHEDULING AND ROUTE PLANNING

Mechanical and plant engineering is at the heart of industrial performance as a supplier of complex products for all sectors of the economy. The European mechanical engineering industry is the global leader of this sector and Europe's biggest industrial employer. In the areas of Industry 4.0, resource-saving environmental protection, energy efficiency and electromobility, the sector is also a key driver of innovation.

But the industry sector is also facing immense challenges. The traditional capital goods business is coming under further pressure from increased competition. Therefore, the importance of the aftersales and service business is increasing in order to stand out from competitors and open up new growth opportunities.

This is where innovative service solutions come into play: remote support, service apps for customers, predictive maintenance and the optimisation of on-site technician deployments. Mechanical engineering and plant manufacturers are increasingly relying on modern software solutions that support service and enable a new customer experience.

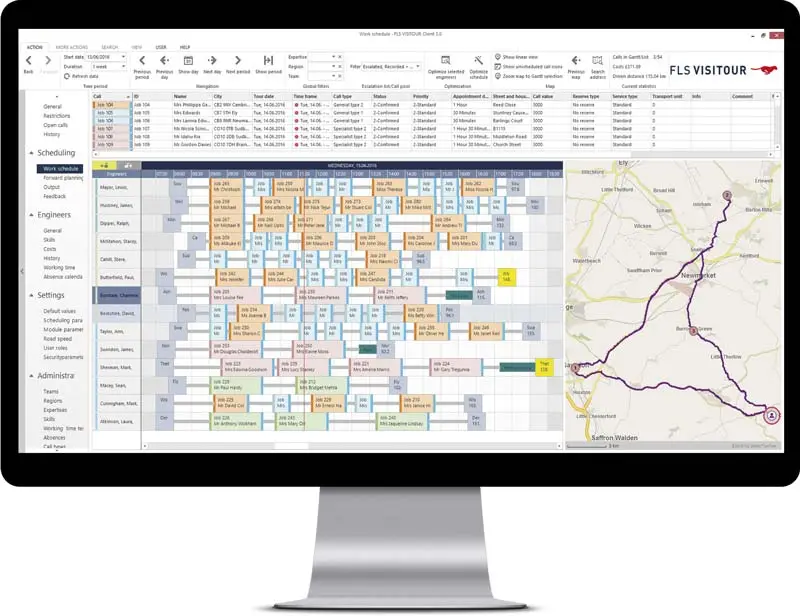

Field service engineers in machinery and plant engineering are highly qualified specialists. The efficient deployment of these resources is connected with a number of conditions. FLS VISITOUR ensures accurate scheduling of service engineers, thus considerably enhancing the 'First-Time-Fix-Rate' and the number of appointments per day. Discover more about the route planning software FLS VISITOUR in machinery and plant engineering in our case studies on Jungheinrich and Gilbarco.

With our solutions, we help companies to optimally and efficiently manage the assignments and tours of their technicians. Our customers benefit from leading software for field service management, the use of which quickly results in reduced costs and increased customer and employee satisfaction.

"Even if we calculate very conservatively and assume a saving of only savings of only 10% of the travel time, we gain 100 hours per week. By saving this valuable time, our time, our employees can now concentrate even more on the concentrate even more on the customers. A great result."

Stefan Bernhard, Christ Wash SystemsFLS SOFTWARE FOR ROUTE PLANNING IN MECHANICAL ENGINEERING AND PLANT CONSTRUCTION

Whether mechanical engineering, plant construction or other companies from the manufacturing sector - the order books are full, personnel is sometimes in short supply. When it comes to order processing, speed, security and customer service are in demand.

Therefore, with FLS VISITOUR, we have developed a field service management solution that really meets these criteria. The key to this is the unique PowerOpt algorithm. PowerOpt is the result of over 10 years of development and research into the logistical problems of deployment and route planning.

Technology makes it possible for you to finally map the complex requirements of field service optimally. And in real time, even if changes occur during the course of the day.

FLS software solutions enable companies to fully exploit their potential to save costs and increase efficiency. This is because the planning processes, tours and routes can be significantly optimised thanks to the unique PowerOpt algorithm. With solutions from FLS, you get automated route planning and route optimisation that gets the most out of your order books.

Our software for your deployment and tour planning or your field service management plans the day in a matter of seconds. This gives your employees time for the essentials, such as escalation management.

You can plan service calls fully automatically according to the according to different types of operation and take into account the relevant relevant factors for each customer.

The system optimally assigns your technicians to jobs according to their skills and availability. This speeds up order processing and increases the success rate. Real-time material handling ensures that all parts needed for the job are available.

Optimised planning makes your processes more efficient, reduces time lost and miles driven. You optimally deploy your service technicians and create a more productive processing of orders.

SUCCESS STORIES FROM OUR CUSTOMERS IN THE MACHINERY & PLANT ENGINEERING TECHNOLOGY SECTOR

Discover how you can advance your technical service with software solutions from FLS through the case studies of our customers. Practical examples show the potential for optimisation that lies in modern solutions for the mechanical engineering and plant construction industry.

FLS CUSTOMERS WITHIN THE PLANT & MECHANICAL ENGINEERING SECTOR

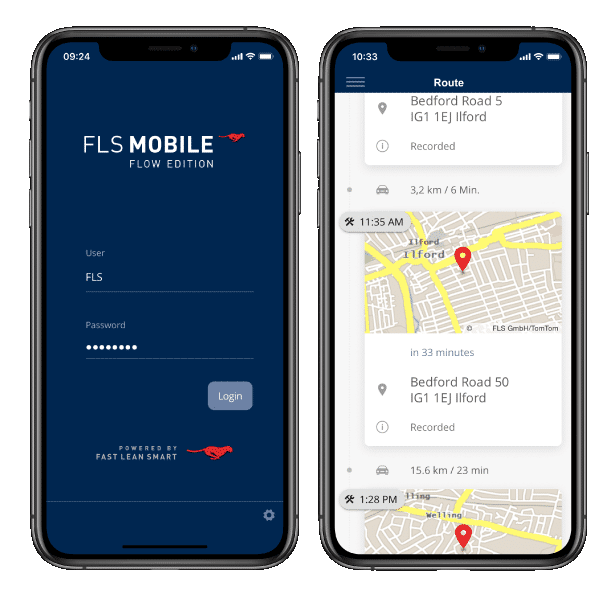

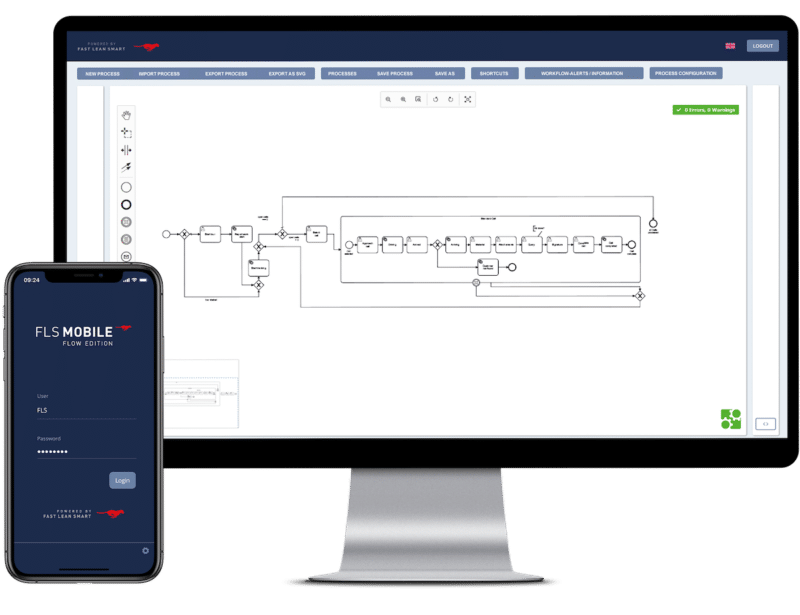

AND THERE'S MORE: MOBILE SUPPORT FOR YOUR TECHNICIANS

With clever Field Service Management solutions for Machinery & Plant Engineering.All process steps - from sending a qualified technician to performing the prescribed tasks on site - all are regulated for medical device manufacturers. In combination with the FLS software for route planning FLS VISITOUR and the mobile app FLS MOBILE, shift tours are optimally planned for the service technician or field service and is intuitively guided through all points on a mobile device while on the move. This avoids errors, automates documentation and increases customer satisfaction through a higher first-time-fix rate.

With FLS MOBILE, your technicians get exactly the information they need to deliver ideal service and increase customer satisfaction. Our mobile field service management application is tailor-made for technical service in plant and mechanical engineering and supports you every step of the way. Your technicians always have the service history and relevant forms at hand. They can create new work orders and directly record the customer signature after completing the order. Thanks to the mobile support, errors can be avoided and your technicians can do their work faster.

Part of high safety and quality standards are careful documentation of all processes in order to be able to trace the application and distribution channels in case of errors or damage. You must ensure that maintenance, repair and reconditioning is carried out regularly and by professionals. FLS understands the importance of being able to comply with your regulations and processes and supports you with specially developed features such as quality metrics, photos, signatures and detailed monitoring and analysis.

MEET THE OPTIMISATION POTENTIAL WITHIN YOUR ORGANISATION

FLS software optimises the Machinery & Plant Engineering industry. We'll show you how, just contact us using the form.

Alternatively email info@fastleansmart.com

or phone +44 1183 800189

Further reading:

Learn about FLS integration with your ERP:

SAP ERP and Microsoft Dynamics 365 ›

FLS Partners who can provide specialist advice on integration with their own technologies:

Find an FLS Partner ›