BLOG / SOLUTIONS · FIELD SERVICE MANAGEMENT SOFTWARE

COST CONTROL: REACTIVE MAINTENANCE WITH FIELD SERVICE MANAGEMENT SOFTWARE

6 August 2021 · James Alex Waldron

WHAT IS REACTIVE MAINTENANCE?

Reactive maintenance in homes, housing or commercial premises (facilities management) is a necessary reaction to equipment producing unplanned or unexpected results. When you consider that this can involve storm damage (structural), a faulty door entry system (electrical), or even a gas leak (a danger to life), it’s easy to see how such tickets can arrive 24/7. Often this evokes a crisis response from tenants and building managers, and in certain cases, the knock-on effects mean disruption, such as moving people away from their homes or place of work.WHY IS REACTIVE MAINTENANCE SO COSTLY TO FIELD SERVICE?

As a provider of skilled technicians and engineers, how an organisation manages its facilities and estate has a direct bearing on your workload and profits. Backlogs, parts, and business continuity costs will escalate when you’re called upon to provide service quickly—it's clearly preferable to mitigate these risks with scheduled predictive maintenance and the analytics to match. For field service response companies, reactive management practices are known to generate cost through calls to recurrent asset failures, imprecise responsibility, more work for dispatch and scheduling teams, and an uninspired field workforce.WHAT ARE THE COST RISKS TO HOME AND HOUSING FIELD SERVICES?

Further, for the unescapable, unscheduled repair, you must question the longer-term opportunity costs associated with your contract and how these financial impacts are accounted for on your balance sheet. Which customer appointments will you delay or reschedule to attend this job? What are the travel and time costs in your reaction? Can you meet an SLA? What is the reputational cost? Does the response require a part that you stock, or a unit replacement or loan that requires specialised logistics?HOW TO CONTROL REACTIVE MAINTENANCE COSTS IN FIELD SERVICE

How do productive and efficient field service providers turn these risks into profits? The critical first step is clean-up of your back-office systems; by deploying a modern ERP and integrated CRM. Mirroring your operational processes to include works data (people, travel, parts) from customer and contract profiles means gaining a single source of truth and transparency. This visibility across your organisation will show the costliest processes that require immediate efficiency improvements.Read more: Introducing Route Planning into your ERP software

If achieving transparency is an essential part of the cost control puzzle, the next is to determine where the revenue leaks occur, and how to fix them. Regular examples in housing and home maintenance field service are uncategorised costs and unbilled expenses. In beginning with KPIs, you're setting your own cost frameworks and subsequent red flags. How are miles driven administered? What are the actual productive hours? And for the reactive maintenance market, what is the first-time-fix success rate?

Read more: What are the most important KPIs for Field Service Management?

This highlights a major hurdle for ERP and CRM systems–the real-time tracking and managing of what happens in the field. An ERP might compute the cost of field staff as they sit waiting in a building or depot, but cannot account for the true cost of their instruction, and what can be learned from the data this generates. Field Service Management software (FSM) is the solution. Because it may seem desirable that the ERP or the CRM has all possible functions for controlling the field service. But such supposed shortcuts nullify all previous cost control measures. Moreover, the right field service management software (FSM) can be connected to the ERP or CRM via interfaces.

FIELD SERVICE MANAGEMENT SOFTWARE TO CONTROL COSTS

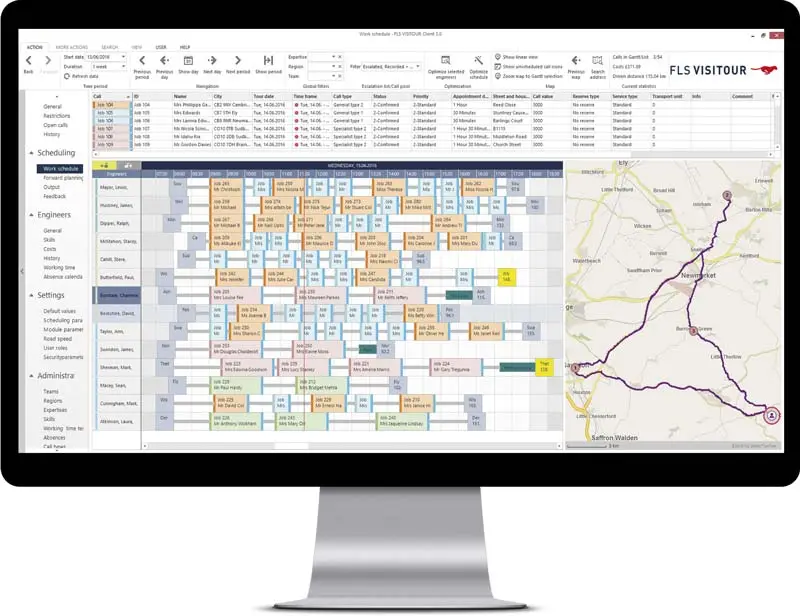

What costs can field service software control? It begins when a reactive maintenance ticket is logged. Consider this high-level workflow.- A dispatch manager receives a ticket via their CRM into FLS VISITOUR. With one click the system finds two nearby operatives. One is employed, the other a sub-contractor. Due to their previous experience of the site, the system is set to take preference of the employed operative.

- The algorithm reworks the existing routes according to operatives’ skills, the SLA, and parts available. It creates availability in-shift. The customer is notified automatically and accepts the appointment on a self-service portal on their mobile device.

- The engineer is directed to the site in the best time possible, having been automatically supplied a route that balances weather, CO2, time-of-day driving speeds and fuel costs.

- The customer that the engineer was originally to attend is now supplied engineer the sub-contractor, who has had their own schedule optimised automatically. This is possible thanks to the removal of hard borders (like post codes).

- Using FLS MOBILE the engineer notifies the scheduling & dispatch team of their arrival.

- The engineer has the ticket detail fed directly from the CRM to FLS MOBILE.

- For cost transparency, they take a photo of their work and attach it to the ticket.

- They notify FLS VISITOUR that the reactive maintenance is complete. FLS VISITOUR gives them their next route and notifies the next appointment with a one-hour window. That customer can track the operative's live location on a map.

- FLS VISITOUR learns the duration of the ticket and this data is fed automatically back into the AI engine.

In this example, the most visible result is that the customer has been serviced quickly. It is however, the background processes that have controlled the cost and expenditure of the ticket. The software has allowed the head office team to instantly optimise and schedule the callout, reducing time and money across the department. There is no longer a requirement to disappoint existing (predictive maintenance) customers, or chase field employees for data.

Inventory levels were automatically adjusted, and at the time of invoicing, measured driving and productivity costs are available to publish.

Choosing to control field service costs with purpose-built software will leave your organisation with a refreshed customer centricity and the ability to attend reactive maintenance callouts with a competitive edge. Boosting efficiency should increase profit, remove wasted time and effort, and create capacity to win loyalty and take on new maintenance contracts.

CONTROL REACTIVE MAINTENANCE SCHEDULING IN YOUR FIELD BUSINESS

To gain an understanding of tools to optimise the field experience and manage costs for your workforce and customers book a short discussion or contact us at info@fastleansmart.com.Read more:

Route scheduling: outpacing timesheets and Excel

Field service automation: next generation Field service

Interfaces: ERP and CRM integration in record time with API

JAMES ALEX WALDRON

UK Marketing Manager

+44(0) 1183 800189

Send email

James Alex Waldron has worked in written communications for over 10 years. Since 2021, he has written for FLS and the Solvares Group on the topics of digital field service transformation and mobile workforce management, and regularly provides insight to the industry press.