Blog / Solutions · FIELD SERVICE LOW-CODE AUTOMATION

OPTIMISING TOTAL COST OF OWNERSHIP (TCO) WITH LOW-CODE AUTOMATION

4. February 2025

James Alex Waldron

T

he manufacturing industry, particularly in Europe and the US, is undergoing a profound digital transformation as a means to remaining competitive. A key focus of this transformation is the digital automation of field service operations: Enabling manufacturers to become more proactive and deliver personalised customer experiences. These advancements drive service growth, reduce costs, and optimise the total cost of ownership (TCO) for end customers.

OPTIMISING TOTAL COST OF OWNERSHIP (TCO) WITH LOW-CODE AUTOMATION

The first step in proactive field service operations is the enablement of real-time analysis through connected asset data - detecting mechanical faults and error states. This is paired with business processes that alert service teams (and frequently, the end customers) with predictive asset health recommendations. Initially, human intervention is often required to triage alerts and determine the best course of action, such as scheduling a field maintenance visit.

However, as confidence in algorithms grows, these processes evolve into full automation, eliminating manual triaging and enabling seamless execution of end-to-end service workflows.

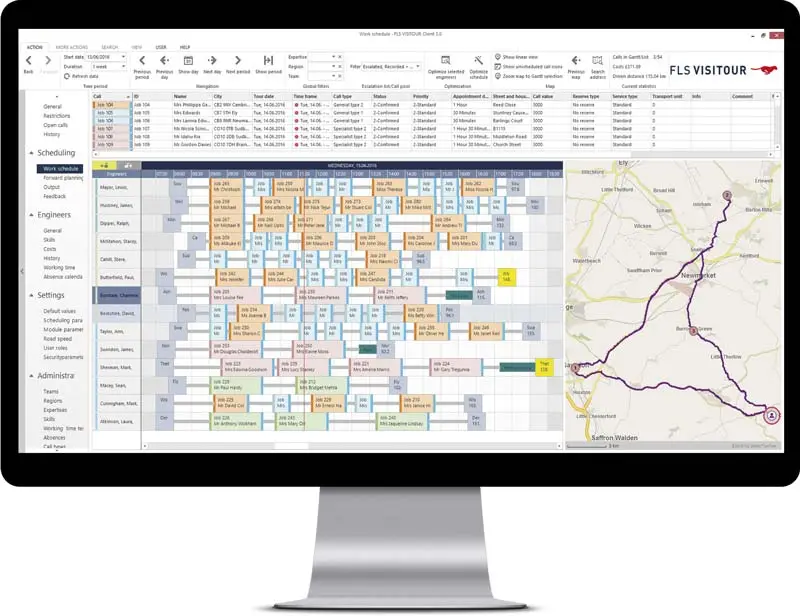

A critical component of this evolution is dynamic field scheduling and embedded route planning. This ensures the right maintenance job is scheduled at the right time to guarantee asset uptime. Real-time field scheduling bridges the gap between issue detection and resolution, allowing for optimised resource allocation and automated task assignments. This reduces downtime, enhances operational efficiency, and improves service quality at scale.

With real-time updates and data-driven coordination, insights from automation are transformed into swift and effective field responses, maximising the value of connected assets. By implementing proactive asset health monitoring and automation initiatives, industrial asset manufacturers can guarantee asset uptime as part of their service contracts.

Servitisation describes a business model trend, away from the pure sale of a product towards the provision of (additional) services. For companies, this means rethinking what added value they can deliver and how they can retain their customers.

SERVITISATION: FIELD SERVICE OPPORTUNITIES FOR MANUFACTURERS

For manufacturing companies, the combined approach means more turnover per customer without much effort; selling the required 'know-how' that is readily available. In its completion, servitisation becomes product-as-a-service or solution-as-a-service.

Over the past decade, FLS Partner Waylay and their platform's digital twin modelling features have allowed their customers to roll out AI-powered predictive asset health monitoring rules and automation flows for connected assets. This has brought them the following tangible operational benefits:

- For every 10K assets in the field, immediate savings are expected to amount to 2.25M EUR per year

- Reducing response time from 24h+ to several minutes using proactive alerting

- A typical accuracy of 80% in predicting machine shutdowns and customer complaints over the next 5 days

- Warranty cost reduction by a factor of 4 when the machine issue is addressed before failure

- 45% less time spent per work order due to the proactive root cause analysis and recommended actions taken

- Autocorrelation of asset issues shrinks the volume of work orders by 35%+

WAYLAY AND FLS VISITOUR: A DEVELOPED INTEGRATION ADDS WORLD-LEADING FIELD SERVICE AUTOMATION

Waylay feeds the FLS VISITOUR scheduling engine with the necessary data to schedule field visits efficiently, and in real-time. This includes:

- Job priority, including critical in-day response capability

- Grouping proactive issues into a single visit

- The spare parts required for the job

- The estimated time of the job duration, with self-learning functionality for future planning

- The predicted time to failure

- Required field operative skills

- Optimised time-of-day routing

FLS VISITOUR will now schedule and assign maintenance jobs taking into account:

- Availability of field service resources with the necessary skills and certification

- Existing jobs planned for the asset or other assets at the same location

- Minimised travel time

WATCH: Developed integration - Waylay and FLS VISITOUR for proactive asset inspection scheduling:

FLS' unique PowerOpt algorithm considers the entire workforce schedule at once, bringing the following tangible service operations benefits:

- 36% average reduction in travel distance and time

- 11% average increase in field service team capacity

- 1.3 average additional appointments per shift

- 99.5% improved SLA adherence

- 20-30% improvement in first-time fix rate

REALISE A COMPETITIVE ADVANTAGE WITH A UNIQUE FIELD SERVICE SOLUTION

We evaluate your field organisation's process efficiency, planning quality, and cost structure. To gain an understanding of tools to optimise the field experience for your workforce and customers book a short discussion or contact us at info@fastleansmart.com.

Read more:

FLS Partners With Waylay: Developed Integration Redefines Automation

What is After-Sales field service?

Maximise First-Time Fix rates with Business Intelligence data

Predictive Analytics: Creating efficiency for Field Service operators

BPMN Modelling: Benefits for Field Service processes

Why smart Field Service Automation needs smart data

JAMES ALEX WALDRON

UK Marketing Manager

+44 1183 800189

Send email

James Alex Waldron has worked in written communications for over 15 years. Since 2021, he has written for FLS and the Solvares Group on the topics of digital field service transformation and mobile workforce management, and regularly provides insight to the industry press.